Enhancing Manufacturing Productivity Through 5G Indoor Location Technology

In the ever-evolving landscape of manufacturing, 5G indoor positioning technology is set to revolutionize the industry, paving the way for continuous advancement and smarter facilities. This cutting-edge technology accelerates and amplifies smart factory investments by offering ultra-low latency, highly reliable, and precise location tracking within manufacturing facilities.

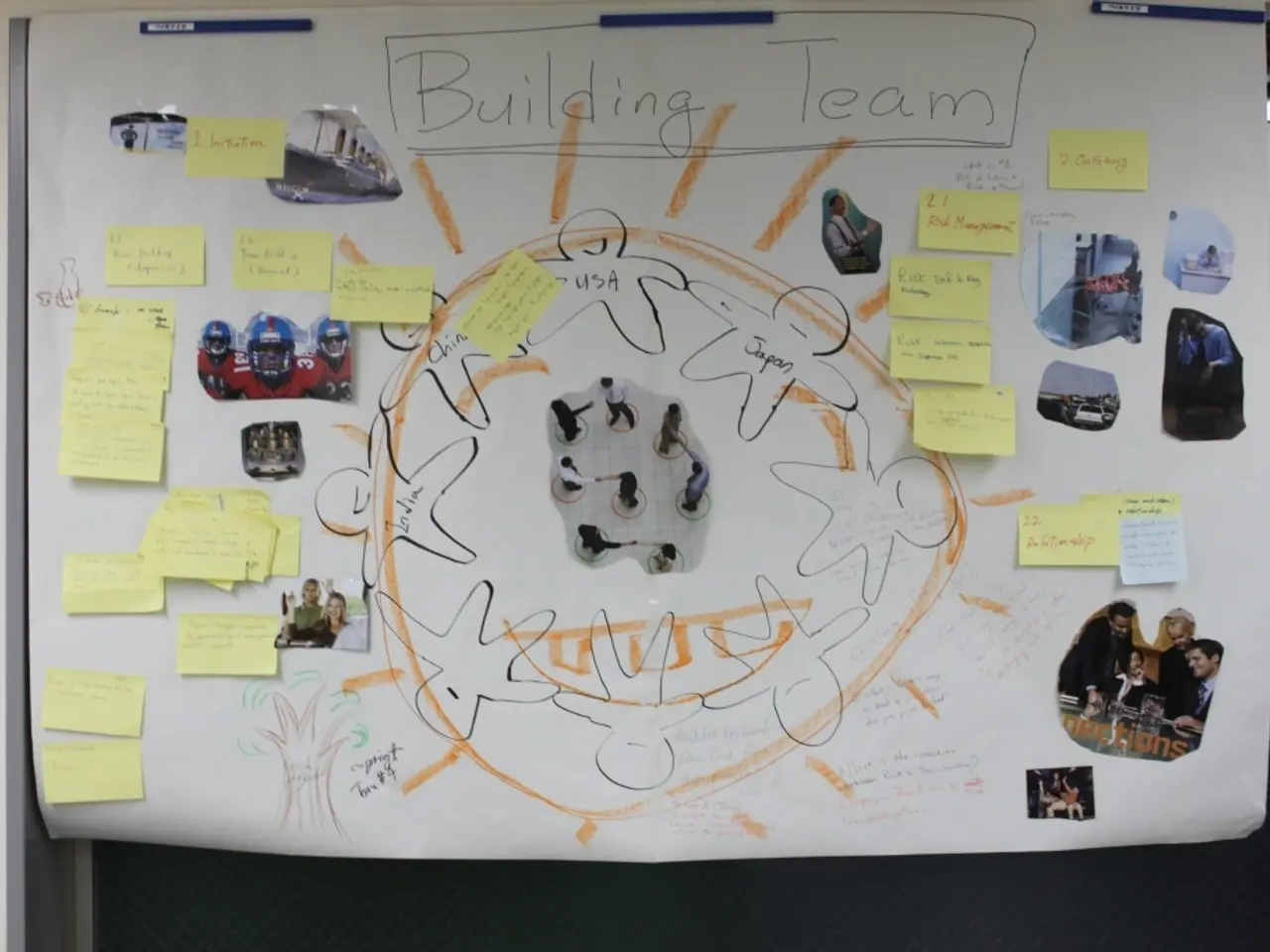

By integrating 5G with indoor positioning, factories can achieve higher productivity, improved operational efficiency, and significant cost savings. This integration enhances automation, robotics control, predictive maintenance, asset tracking, and safety monitoring - all critical pillars of smart factories.

One of the key benefits of 5G indoor positioning is its ability to deliver ultra-low latency and real-time responsiveness. This capability enables robots and automated guided vehicles to navigate dynamically and safely with real-time location data, increasing automation and throughput.

5G also ensures high reliability and coverage over large indoor areas, supporting seamless communication between sensors, machines, and edge computing systems for real-time monitoring and control. Moreover, it accommodates thousands of connected devices and sensors simultaneously, crucial for comprehensive asset and personnel tracking.

Enhanced data availability is another significant advantage of 5G indoor positioning. Massive data transmission supports advanced analytics, digital twins, and AI-powered decision loops that optimize factory workflows, predictive maintenance, and quality control.

Flexibility in factory layout is another key benefit. With private on-premise 5G networks featuring precise indoor positioning, factories can redesign or expand their floors without connectivity gaps, supporting new production processes and rapid adaptation.

Examples show 20-90% improvement in productivity, 55% labor cost savings in warehousing, and 40% lower operating costs in terminals directly linked to 5G-enabled smart operations.

Practical considerations for deploying 5G indoor positioning in manufacturing facilities include private 5G infrastructure tailored to the factory’s specific needs, integration with existing systems, site-specific design, robust cybersecurity measures, cost and complexity management, and complementary technologies such as Wi-Fi 6 and Bluetooth.

In conclusion, 5G indoor positioning catalyzes smart factory investments by delivering precise, real-time location data and a dependable communication infrastructure that drive automation, efficiency, and innovation. Practical deployment requires tailored private 5G networks designed to factory layouts, integration with IoT ecosystems, and strong security to fully realize smart manufacturing’s potential.

This article provides insights into the strategic advantages of a 5G solution and offers practical considerations for its deployment. High-fidelity, accurate positioning data is used in digital twin integration, providing unparalleled operational control and efficiency. Conventional approaches have limitations compared to a dedicated 5G solution, and this integration enhances worker safety through precise location awareness, optimizes industrial asset tracking with pinpoint accuracy, and enables sophisticated predictive maintenance with 5G data.

The 5G indoor positioning technology, integrated with the manufacturing industry, boosts productivity, operational efficiency, and offers cost savings by automating factory processes, enhancing robotics control, and facilitating predictive maintenance. This integration also supports real-time monitoring and control through seamless communication between sensors, machines, and edge computing systems, all of which are crucial in the finance sector for ensuring profitability and investment in the technology. Furthermore, the technology's ability to deliver ultra-low latency and real-time responsiveness, along with its massive data transmission capabilities, paves the way for advanced analytics, digital twins, AI-powered decision loops, and flexible factory layout designs that reflect the demands of the rapidly evolving technology industry.