AI's Impact on Modern Equipment Management Today

AI is transforming the landscape of machinery maintenance, acting as a smart assistant for machinery issues. This technology, often integrated with the Internet of Things (IoT), enables real-time monitoring, predictive analytics, and proactive decision-making.

In the realm of predictive maintenance, data from sensors is collected and analyzed to find patterns, predict when a machine might fail, and action is taken to fix the issue before it causes costly downtime. General Electric, for instance, uses this approach for jet engine monitoring, significantly reducing maintenance costs.

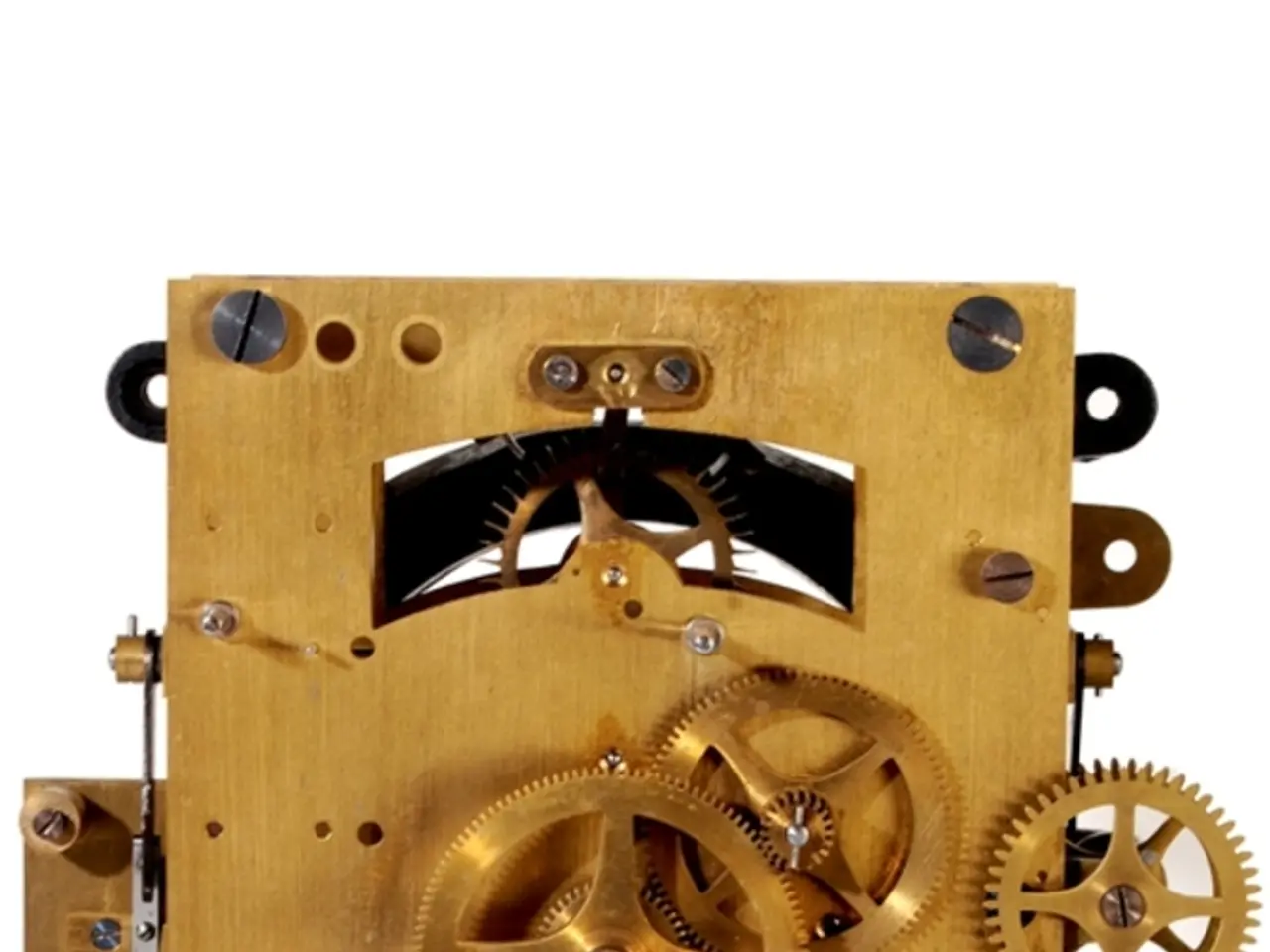

AI-driven diagnostics are faster and more accurate than traditional methods, providing immediate results and high accuracy with data. Sensors on machines can detect vibrations, temperature, and other important factors, and when these sensors send information to AI, it can identify patterns and alert the user if something seems off.

The benefits of AI in machinery maintenance are numerous. It improves operational efficiency, extends the lifespan of machinery, and saves money by preventing downtime. By leveraging AI, companies can ensure that their equipment runs optimally, reducing unexpected failures and maintenance costs.

AI systems learn from historical failures, maintenance logs, and environmental conditions to provide actionable insights and improve future predictions. For example, Shell, in the oil and gas industry, uses AI algorithms to analyze sensor data from offshore drilling rigs, reducing downtime and maintenance costs by about 20%.

In the construction industry, AI-driven predictive maintenance, combined with telematics, provides alerts with failure probabilities for equipment, allowing maintenance to be planned rather than reactive. This approach extends asset lifespan and optimizes repair schedules.

The automotive industry also benefits from AI, with manufacturers predicting vehicle component failures by analyzing real-time sensor and log data. This enhances vehicle reliability, reduces maintenance costs, and improves customer satisfaction.

These examples highlight AI’s role in transitioning industries from costly, inefficient maintenance to optimized, predictive strategies relying on data-driven, automated decision-making systems. Siemens, for instance, employs IoT in their manufacturing plants for machine performance optimization, saving money and boosting productivity.

In conclusion, AI is revolutionizing predictive maintenance by enabling real-time monitoring, advanced anomaly detection, and precise failure forecasting using machine learning models on sensor data from machinery. This approach transforms maintenance from reactive or scheduled routines into proactive, condition-driven interventions, thereby preventing unexpected breakdowns, reducing downtime, and cutting maintenance costs significantly.

Read also:

- Amazon customer duped over Nvidia RTX 5070 Ti purchase: shipped item replaced with suspicious white powder; PC hardware fan deceived, discovers salt instead of GPU core days after receiving defective RTX 5090.

- Twitter profile activity of user 'peng' shows a significant increase in Hong Kong, amidst preparations for the fourth-quarter launch of an extended-range Twitter profile feature

- GPS Tracking System Unveiled by RoGO Communications for Wildland Firefighting Operations

- 17 Tech Gadgets and Add-Ons Permanently Taking Up Space in My Mental Realm